TruHeat’s newest type of heating element is creating quite the buzz.

Let’s find out what exactly is this Amorphous metal tape which is being used by TruHeat in our latest EZ-Heat mats. TruHeat specializes in providing the most energy efficient in-floor heating systems, so it is only fitting that we further improve on our already energy efficient metal tape technology by bringing forth our latest creation…The Amorphous Metal Tape!

HAT IS AN AMORPHOUS METALLIC ALLOY TAPE?

Amorphous metallic alloys, often referred to as metallic glasses, are relatively new materials, mainly available in the form of thin ribbons/tape. They are prepared from molten metallic alloys by a rapid cooling technique. In this technique a ribbon of molten metallic alloy is poured onto a rapidly rotating copper drum.

Due to the thinness of the ribbon 20 to 30 microns, it cools very quickly (at a rate of about 1,000,000 degrees/second). Since solidification occurs so quickly, no crystalline structure has any chance of forming. Instead, an amorphous solid, in the form of a very thin ribbon, is created (the width varies from a few millimeters to 10 cm.

WHAT’S SPECIAL ABOUT AMORPHOUS HEAT TAPE?

Obviously, the lack of any crystalline structure in amorphous ribbons/tape is special. However, other properties of the material are affected by this lack of crystalline structures. The boundaries between crystals in crystalline solids typically cause most of the material’s faults.

The homogeneous, non-boundary structure of amorphous metallic alloys provides unique mechanical, anti-corrosion, wear resistant, and magnetic properties. It makes amorphous metallic alloys superior in many ways to the more common crystalline metals.

WHY DOES IT MAKE SUCH A GREAT HEATING ELEMENT?

Due to the absence of crystalline structure, amorphous ribbons have higher electrical resistance than crystalline solids of the same composition. Together with the physical form of the ribbon, which provides a low mass to surface area ratio, it makes the ribbon a very attractive candidate as a heating element. Why?

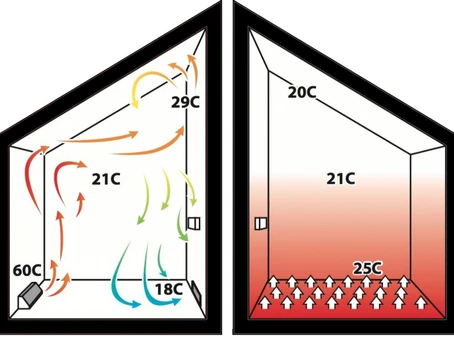

The explanation is very simple: energy transfer from any heating element is proportional to its surface area and the temperature difference between the heater and its environment. The larger the surface area, the lower the temperature difference needed to transfer energy from the heater to its environment.

Since the surface area of the ribbon is relatively large (compared with the surface area of conventional heating wires) it is able to efficiently transfer heat to its environment at lower temperatures. In a domestic heating environment, lower temperature means a healthier environment and greater safety and durability.

TruHeat’s amorphous ribbons are far more effective heating elements than regular heating wires because they provide.

- SAFE SOURCE OF HEAT

- ENERGY SAVINGS

- SUPERIOR HEATING PERFORMANCE

- LONGER PRODUCT LIFE

- SUITABLE FOR ALL LOCATIONS

- LARGE HEAT TRANSFER AREA

- LOWER INSTALLATION COSTS

- NEGLIGIBLE EMF

WILL A NEW TYPE OF HEATING ELEMENT REALLY MAKE THAT BIG OF A DIFFERENCE?

The heating cable technology is something which was developed in the 80’s. Not a lot has been changed with these types of floor heating systems. It is still the same type of copper wire which heats due to electrical resistance and it is still the same wire which stores tons of energy inside of itself before being effective in providing heat. TruHeat’s amorphous metal technology was developed in 2009 and we have learned from the past on how to become better. Therefore, when you go with our amorphous metal equipped heating systems, you can rest assured that you are going with the future of floor heating and not staying in the past.