Amorphous Metal Tape

- Home

- Amorphous Metal Tape

amorphous material

What is an amorphous material?

SAVE ON ENERGY CONSUMPTION

Benefits

KEY ADVANTAGES

SUPERIOR HEATING PERFORMANCE

LONG PRODUCT LIFE

LARGE HEAT TRANSFER AREA

ENERGY SAVINGS

NEGLIGIBLE EMF

3x FASTER HEAT DELIVERY

Differentiation

AMORPHOUS METAL TAPE VS HEATING CABLE

Cable based systems need at least 1 hour to get up to peak performance levels and this tends to get a little heavy on your wallet over time. Due to the thin metallic nature of our heat tape, our heating system will reach peak temperature in minutes. In comparison to hydronic based systems, TruHeat systems also out perform them by delivering the heat when you need it and shutting off once the desired room/floor temperature is achieved. Whereas, the hydronic systems need to keep working all the time otherwise they are not effective since they too need a lot more run time to be effective.

Based on lab tests, TruHeat’s amorphous metal heat tape will achieve its peak 86°F/30°C temperature in merely 3 minutes. Meanwhile, the cable reaches this same temperature in over 10 minutes. This means that the amorphous heat tape starts to delivery heat 3 times faster.

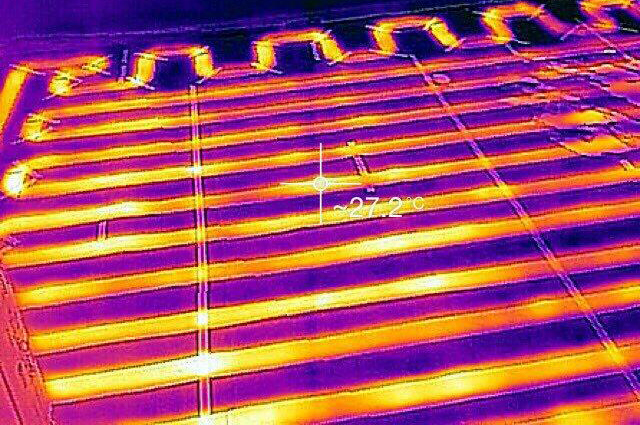

Testing

HEAT TRANSFER TEST

The advantage once against goes to our metallic heat tape in this case. The fact, that the heating tape is so thin also means that the generated heat can easily be sent forth to the surrounding area, making our heating element far more efficient.

In fact, based on lab studies, TruHeat systems offer a 173% better heat transfer rate compared to heating cables as shown in the chart.